Well, it was three summers ago that I worked on the

lithium ion dynamo charging circuit. The lighting system itself worked very well as a 'be-seen' light for riding around the city, especially the rear light, which was really impressive. The LED was very bright, without optics and the lens on the tail light diffused it nicely to make it visible from a fairly wide angle.

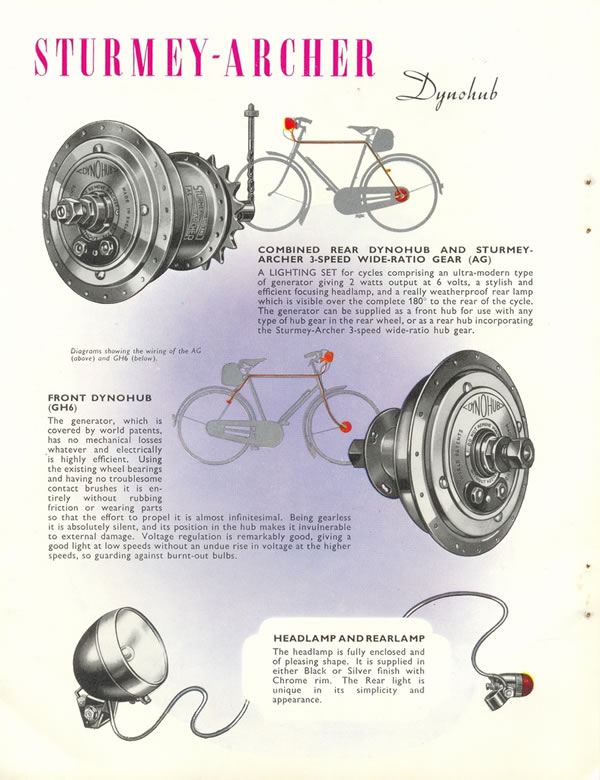

Unfortunately, there were a couple of mechanical and design issues that ultimately led to its retirement. First, the old Sturmey Archer lamp switch was pretty flaky and getting the knob in just the right position to make contact and turn the lamp on could be tedious. The first failure came when one of the internal wires popped loose, most likely due to a combination of vibration and my bad soldering!

The real problem, though, was the lack of a proper load switch in the design. The battery was in parallel with the charging circuit and the LEDs and I think those LEDs could draw more current from the battery than the dynamo could replace while riding. This meant that proper battery charging could only happen during day riding with the lights off. Riding at night for long enough could deplete the battery completely. The charging circuit could provide enough current to drive the LEDs from the dynamo, but they went out, of course, as soon as you stopped.

An improved design would have incorporated a load switch that would disconnect the battery from the LEDs while the bike was moving and connect them only when stopped. However, even lithium ion batteries have a limited lifetime, so in the long run, this design wasn't viable for the obsessive technical idealist in me (in practical terms, with a proper load switch I expect a lithium ion powered standlight would've lasted years).

Commercial dynamo lights use

supercapacitors to store energy to keep the lights on while stopped. Supercapacitors can be charged up very quickly to hold just enough energy to keep your lights on for a few minutes. Better yet, they can be charged and discharged hundreds of thousands of times (or more) before their performance declines. Adding a supercapacitor requires careful design, requiring both the voltage to be strictly regulated as well as limiting the charge current. At the time, I felt such a design was beyond my technical expertise.

Anyway, the lithium ion standlight on my wife's bike didn't get much use; she was very pregnant by the time I finished the project and didn't really start riding again until autumn of 2009. At this point, some of the aforementioned issues arose, but the impetus to start working again on dynamo lighting circuits in earnest came when some absolute

fucker decided that he needed the Sturmey Archer taillight more than my wife's bike needed it. The thief, who knew what he was after, snipped the wire and, with tools he must have brought specifically for the job, removed the taillight and courteously replaced it with a crappy chromed plastic Cateye taillight. Most of the

Raleigh Superbes I see on the street have dangling, unused Sturmey bullet tail lamps, so it was just my luck that probably the only other person in a city of 2.5 million people who had a thing for vintage Sturmey Archer tail lamps happened across my wife's bike and decided to steal the rear light.

Around the same time, I was starting to get obsessed with

vintage French bicycle lights from the 50s and 60s. Unlike their British and American counterparts, who used chromed steel, many French lamp makers used polished aluminum, resulting in many elegant and well-perserved specimens. After several months hanging around Ebay France, I had secured my first set of hammered Luxor lamps.

So, with a nice set of lamps and the demise of my wife's bike's lighting system, I started to look again into designing a modern dynamo-powered LED lighting system with a standlight that could be retrofitted into vintage lamp housings.

Thus far, much progress has been made, which I will chronicle here!